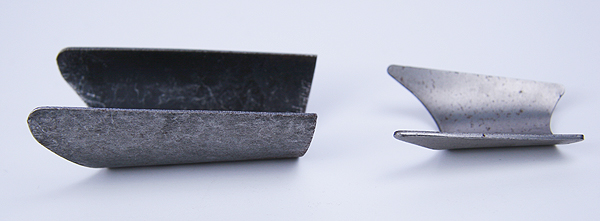

You may have noticed we released some new frames with the same old names, but make no mistake, these frames are different. The obvious difference would be the use of SuperTherm top and down tubes. Read about its properties below. The other major difference would be the down tube gussets we are using now, 3D laser mitered 4130 cro-mo, as opposed to what we used to use, cold rolled steel. The new gussets are substantially larger, the down tubes have been raised and the bottom of the gussets are located where the bottom of the old down tubes were creating a “pocket” between the gusset and tube, this makes for a larger weld area. So now you know.

SuperTherm from True Temper is a proprietary superthermophillic (heat-loving) alloy, developed in partnership with the U.S. Steel Alliance. The composition of Chromium, Molybdenum, and Vanadium with an unprecedented 217 ksi ultimate tensile strength makes this alloy actually gain strength through a metallurgical transformation in the heat-affected zone as a result of welding or brazing. SuperTherm is highly temper-resistant, resulting in an 11% increase in fatigue life and a 20% increase in impact strength heat treated 4130. The increased mechanical properties of SuperTherm allow for incredibly strong, yet lightweight frame designs with that legendary feel of steel ride quality.

Originally Posted by JPR