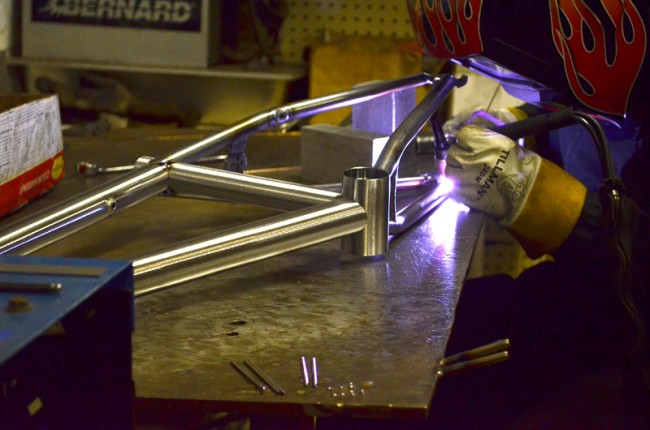

These photos are all from FBM’s Machine shop, where some of the most trusted, quality hand built frames are produced by real life bicycle enthusiasts…

The manufacturing aspect of FBM is one of the strongest, and most prolific symbols of what makes FBM unique and awesome, community driven, hands on, hard working, skilled, DIY energy and creativity.

Through our hands on approach to BMX in general, and especially in our machine shop, we are able to constantly make improvements, keep a close eye on quality control, make efficient and practical use of materials without being wasteful, test out new ideas, work with different types of tubing on prototypes, and beyond.

Innovation can sometimes come from from somebody taking a product already in production and making it better, whether it be with the materials, developing a more accurate and streamlined process, or just advances in design through being involved in the production of a bicycle and actually riding them! This is what we are doing.

Although the cost of a frame built at FBM might be more expensive than some frames, we take the quality control, and steps to ensure a great product is being made, very seriously.While providing real life customer service, we interact with our customers getting useful feedback and more, constantly working on improving all aspects of what we do.. Never mind the environmental impact of sourcing and building locally or that we’ve created jobs locally for people in our BMX community, the fact that we take the time to make a quality product ourselves, is very important to us, to BMX, and the community at large.

All in all, we are proud of what we do at FBM, stoked to be a part of BMX, and we appreciate every person on every level that supports what FBM does!

A lot goes into making a frame at FBM, and in everything we do, because we care, and we hope that gets people stoked!

As John Lee put it- “…we make stuff to the best of our abilities, and with each day, and each frame is a learning experience gained…”

Skip to content